Help electricians who want to sort out their career plateau :

Understanding the underlying principles more quickly

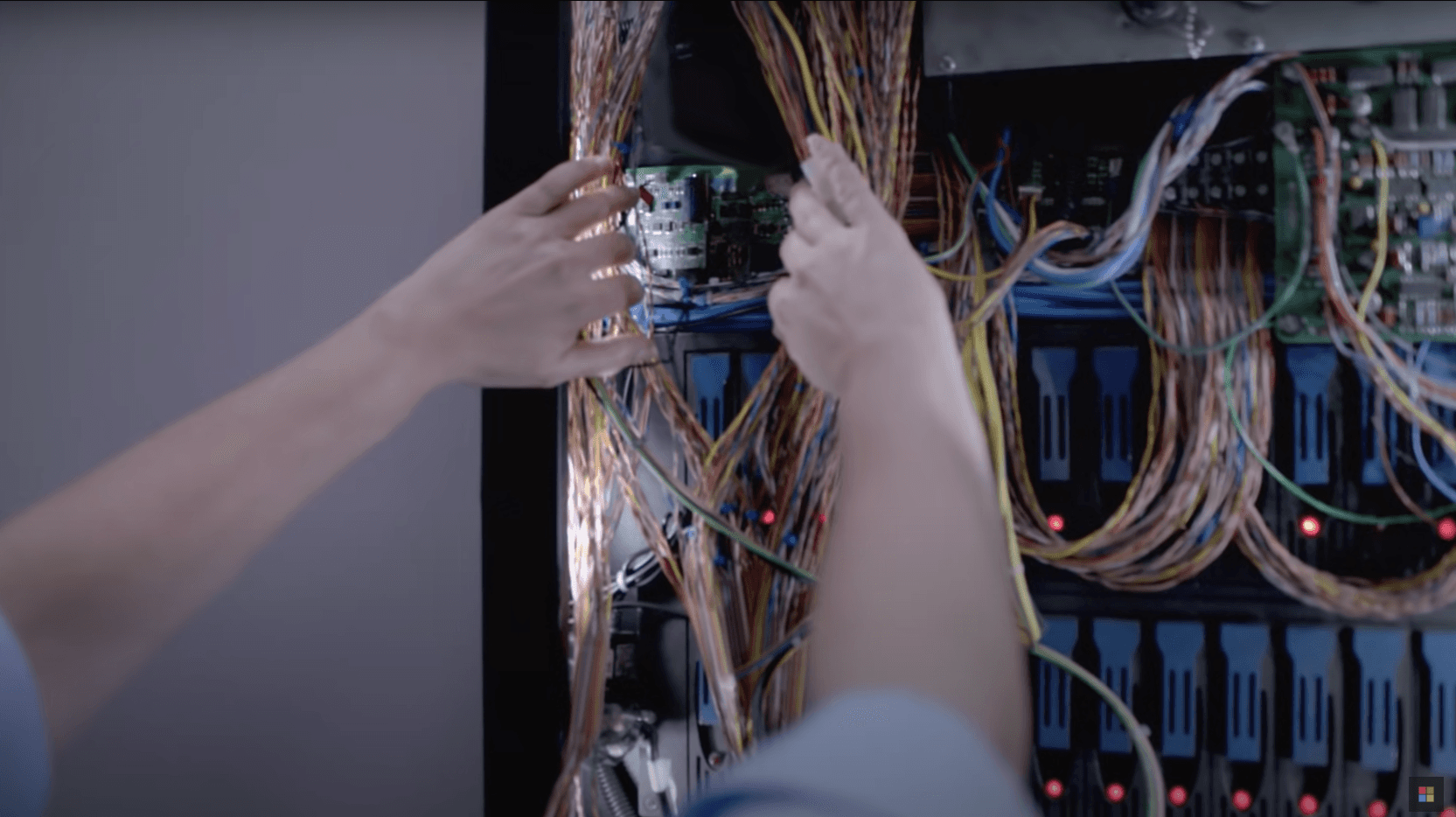

Gain experience in repairing

Four-member Teamwork, Commision

June-August, 2022

My Job: Research + Interview + UX Design + APP UI + Iteration

power bank

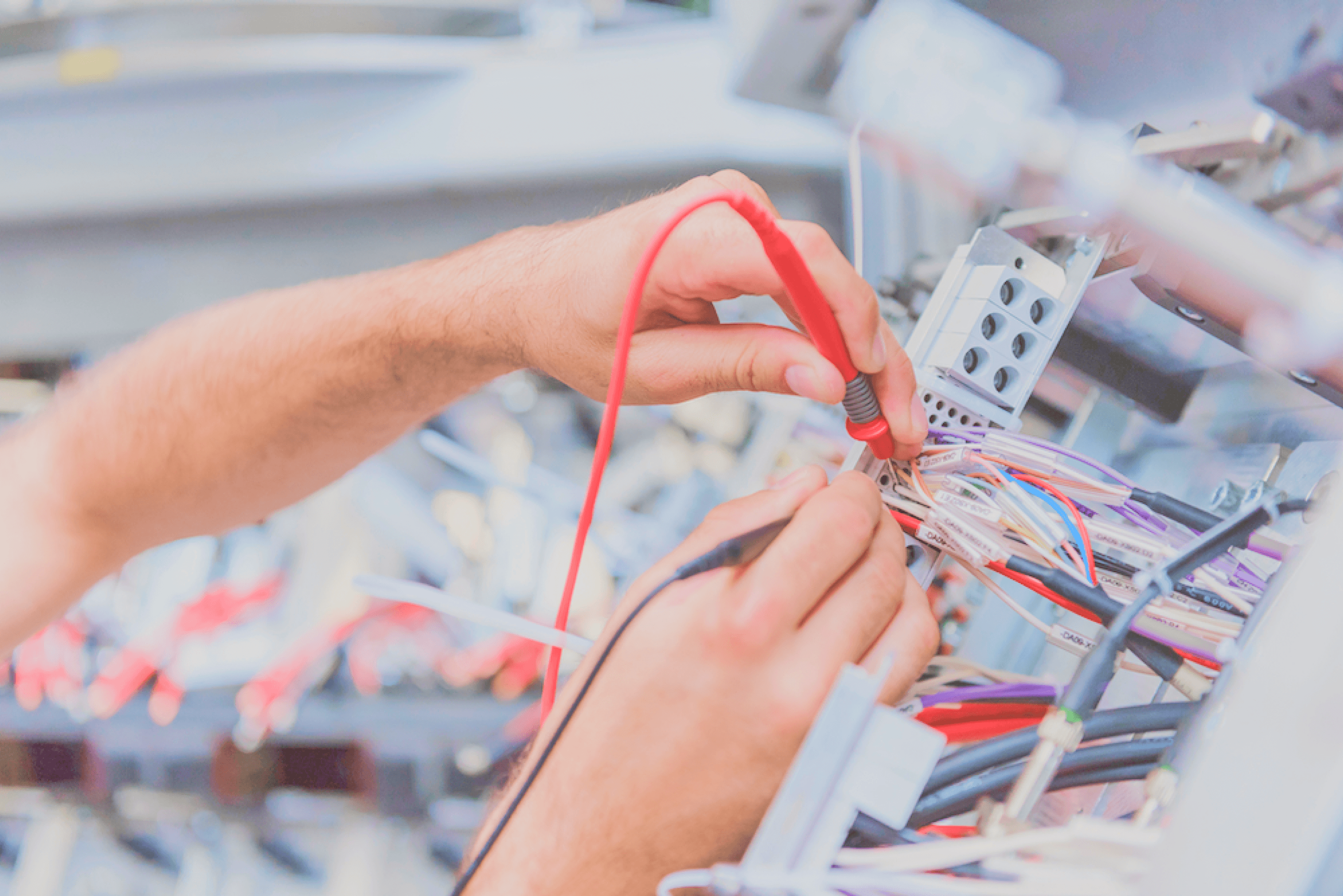

background

Increasing demands

Increasing average age

Revenue of electricians in China, 2021

Insufficient young electricians

>40

The number of electrician occupations is inversely proportional to their earnings.

General electrician careers have a high upside.

Electrician is a highly technical job, which not only depends on experience, but also requires knowledge accumulation.

apprentice electrician

¥3,000-5,000

¥4,500-6,000

¥5,000-8,000

¥6,000-9,000

¥6,500-10,500

¥8,000-10,000

¥8,000-12,000

>¥20,000

maintenance electrician

factory repair/maintenance

decoration/assembly electrician

outdoor electrician

power distribution

manufacturer after sales

electrical technician, senior engnieer

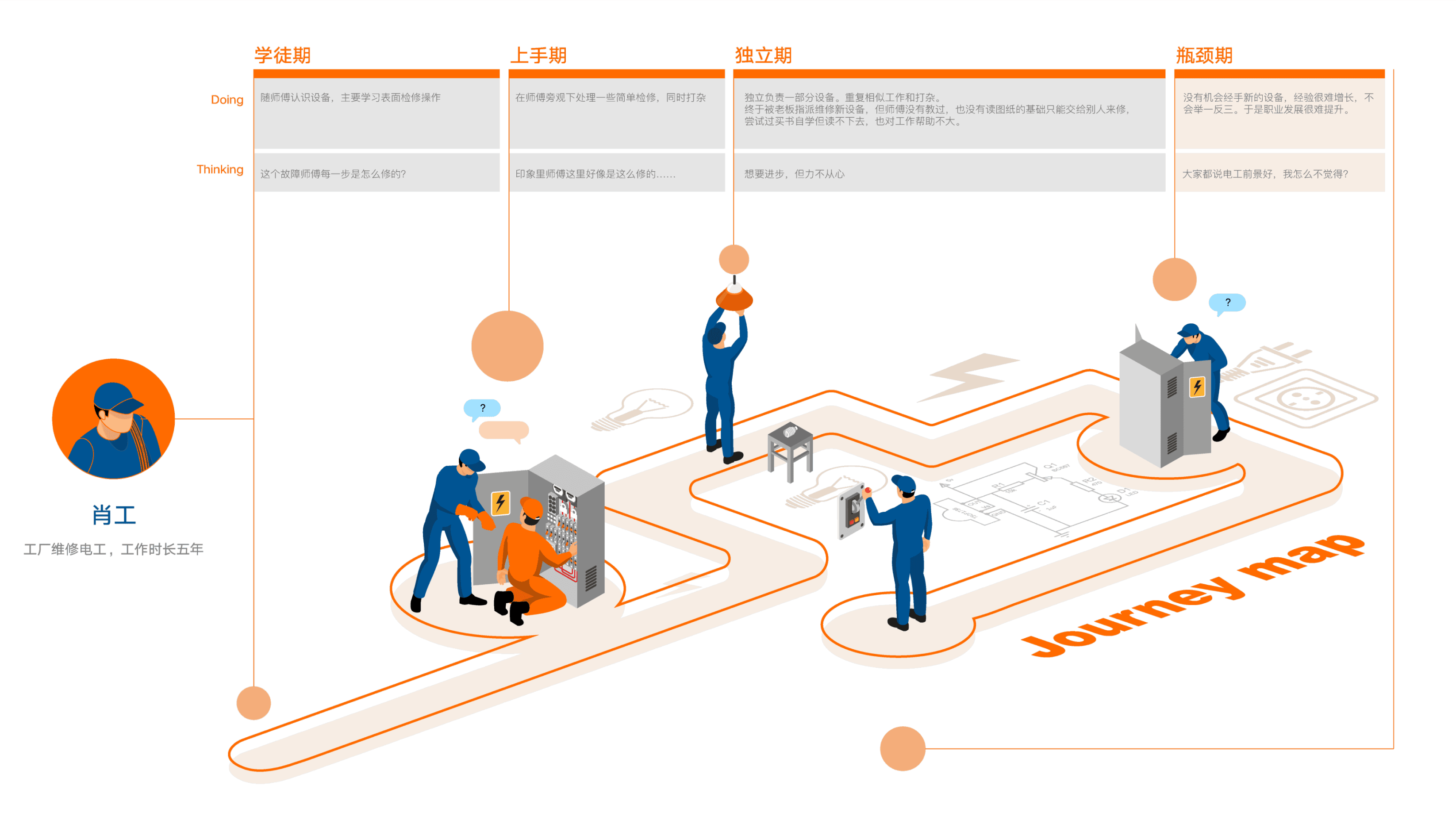

journey map

Rookie

Doing

thinking

Apprentice

Independence

Bottleneck

Joey

Follow the master to recognize the equipment, learn overhaul operation

Handle some simple overhaul under the master's observation

- Repeat similar work and odd jobs

- Couldn't learn to repair new equipments

- Tried to buy books to learn but couldn't read it

Without the opportunity to handle new equipment, it is difficult to grow in experience so and advance in your career.

How did the master repair this fault in each step?

I remember that the master seems to repair like this ...

Tried to get better, but couldn't.

Everyone says electricians have a good future, why don't I think so?

How might We......

Practical Operation

engineering drawings

Physical principles

Current status

knowledge

horizon

Help electricians who want to break out of their career bottlenecks

Gain experience in repairing

Understanding the underlying principles more quickly

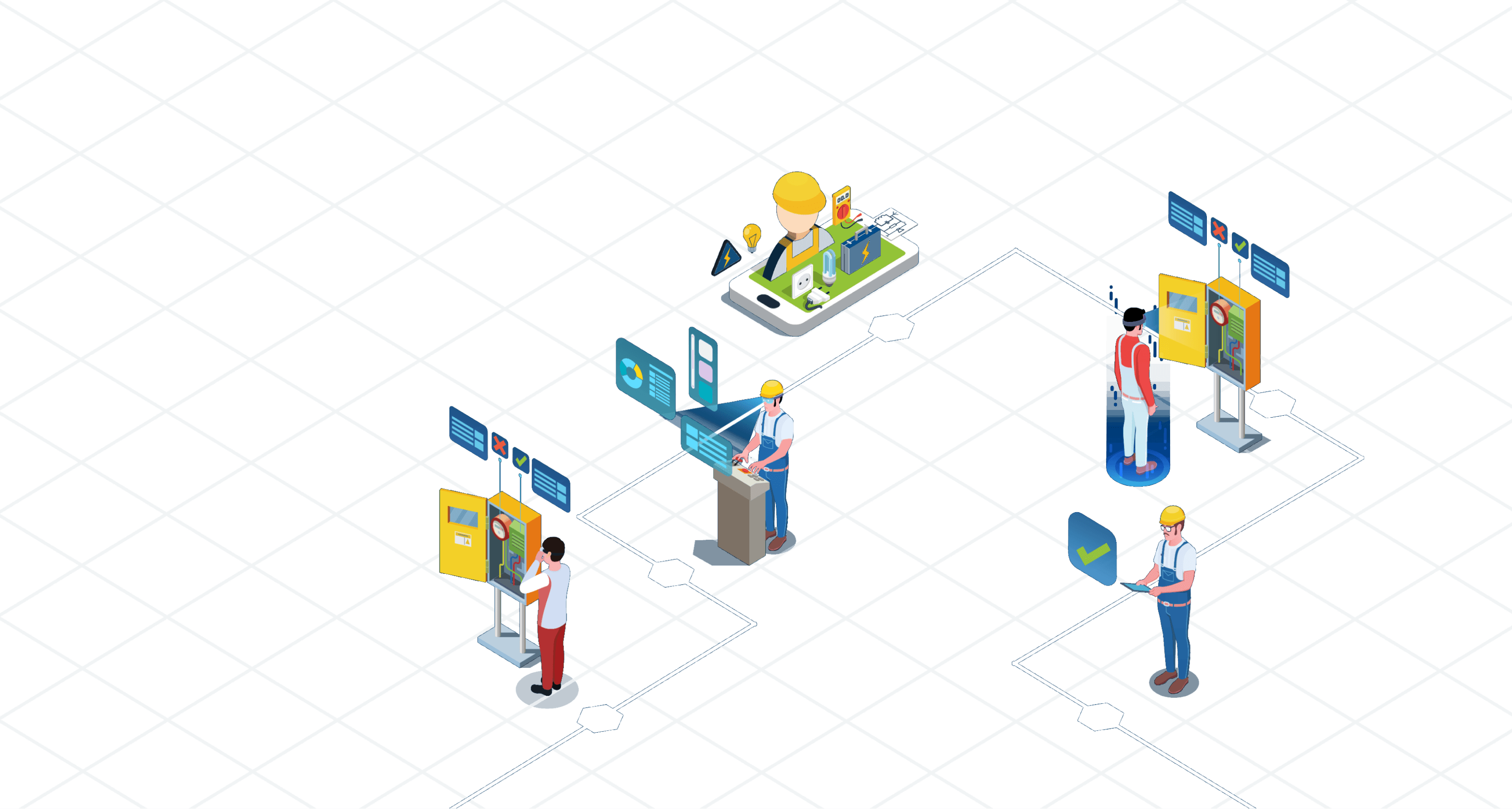

Scenarios

After work

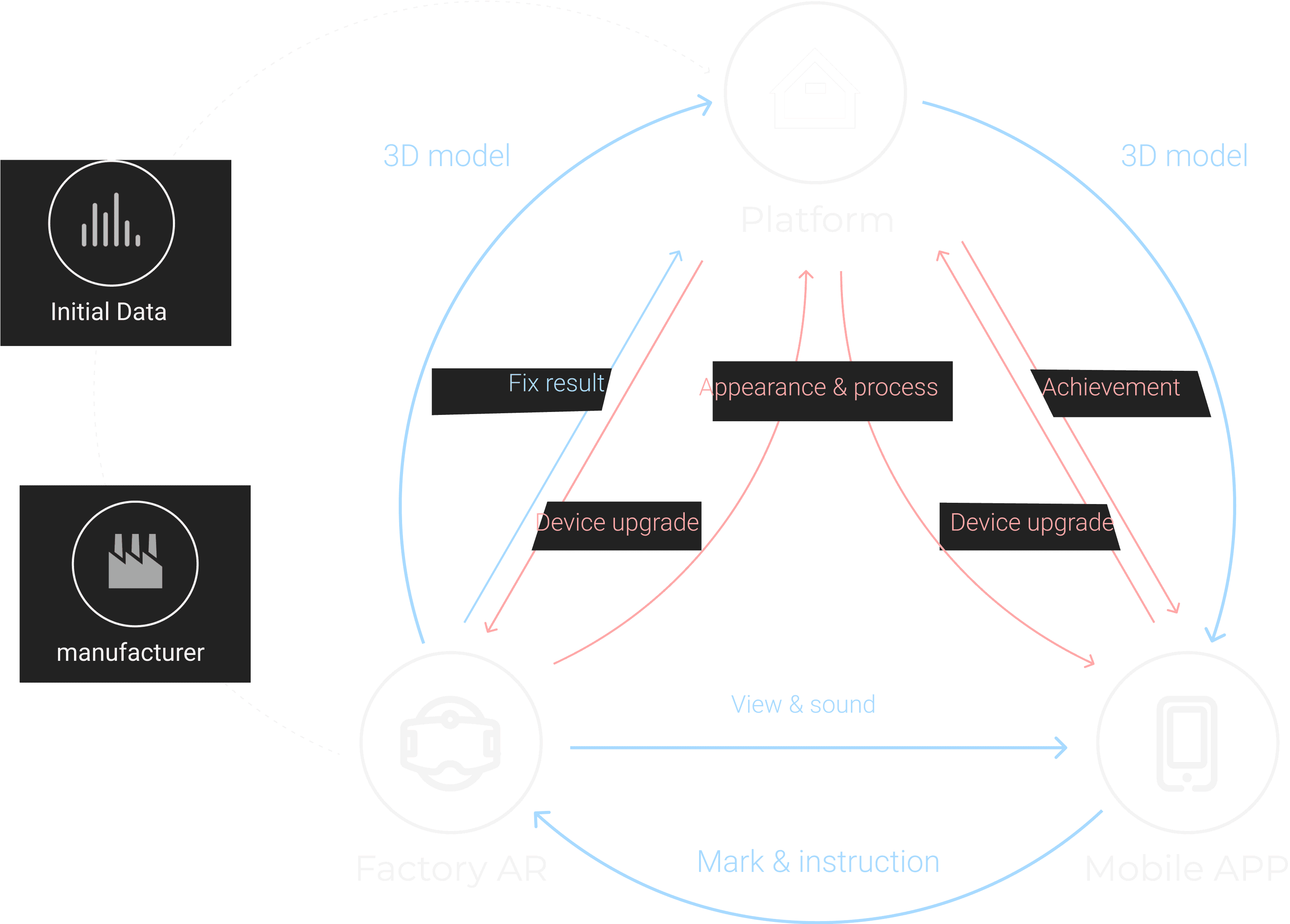

How the system works

Understand circuit principles at work

Assist in completing the work

Connect electrician work and life scenes in series

Jointly assist the improvement of professional knowledge

and skills to break through career bottlenecks

Gather experience out of work

Learn circuit principles from practice

Train for weaknesses

Case resource

Record repair processes and

upload them to database

(Most electricians)

(Enterprising electricians)

Improve performance

Work

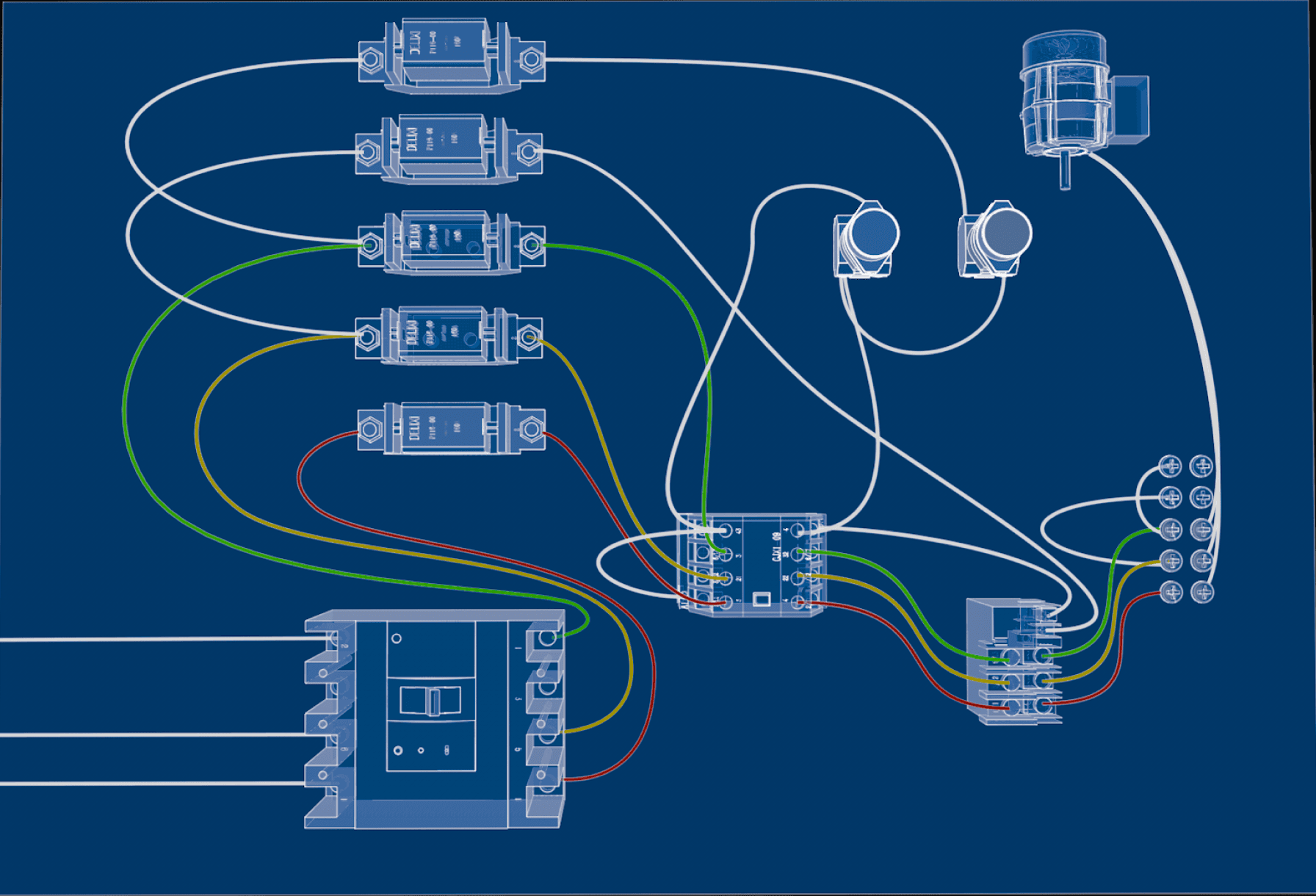

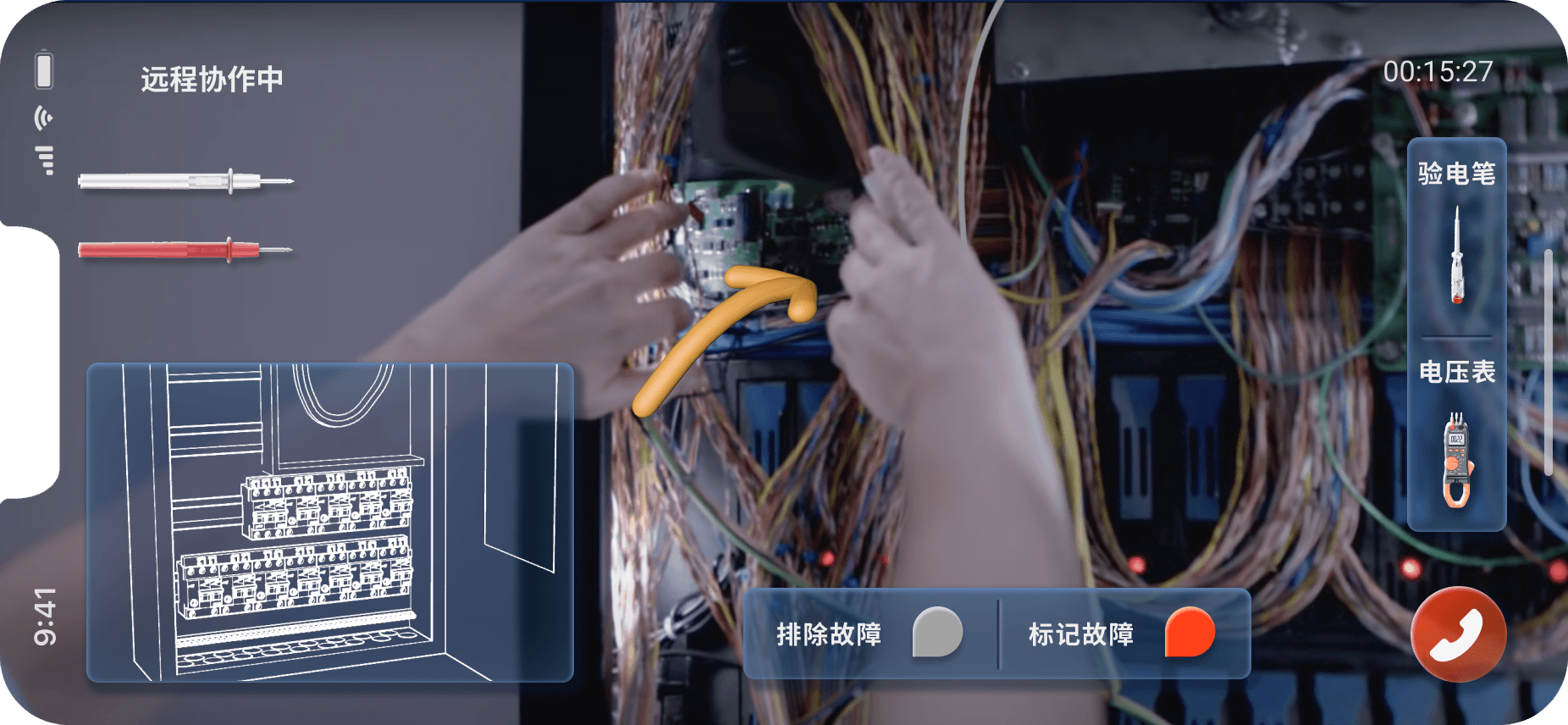

AR Glasses

Facilities

After work

mobile phone app

Information architecture

Induction Training

Remote Aid

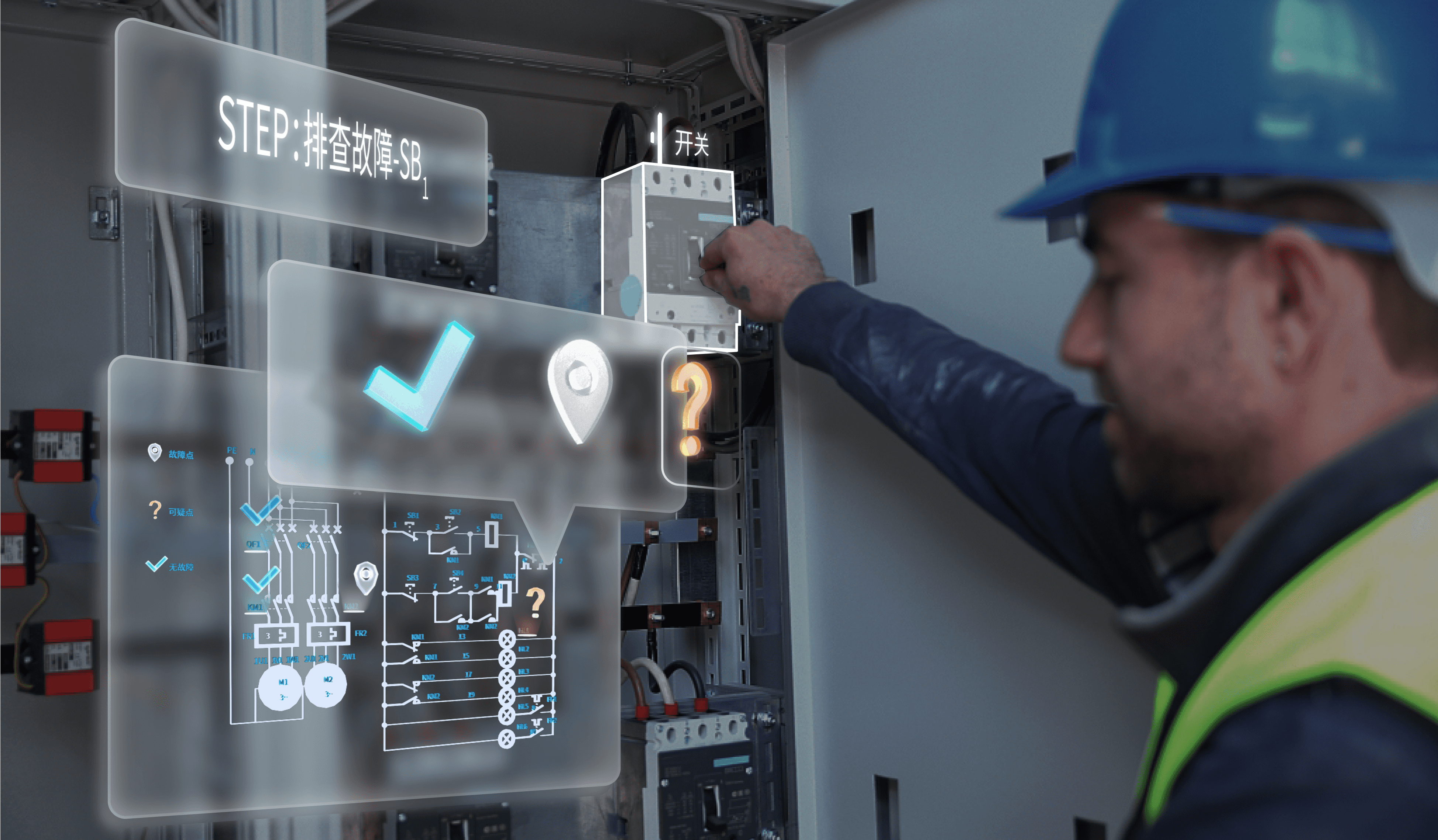

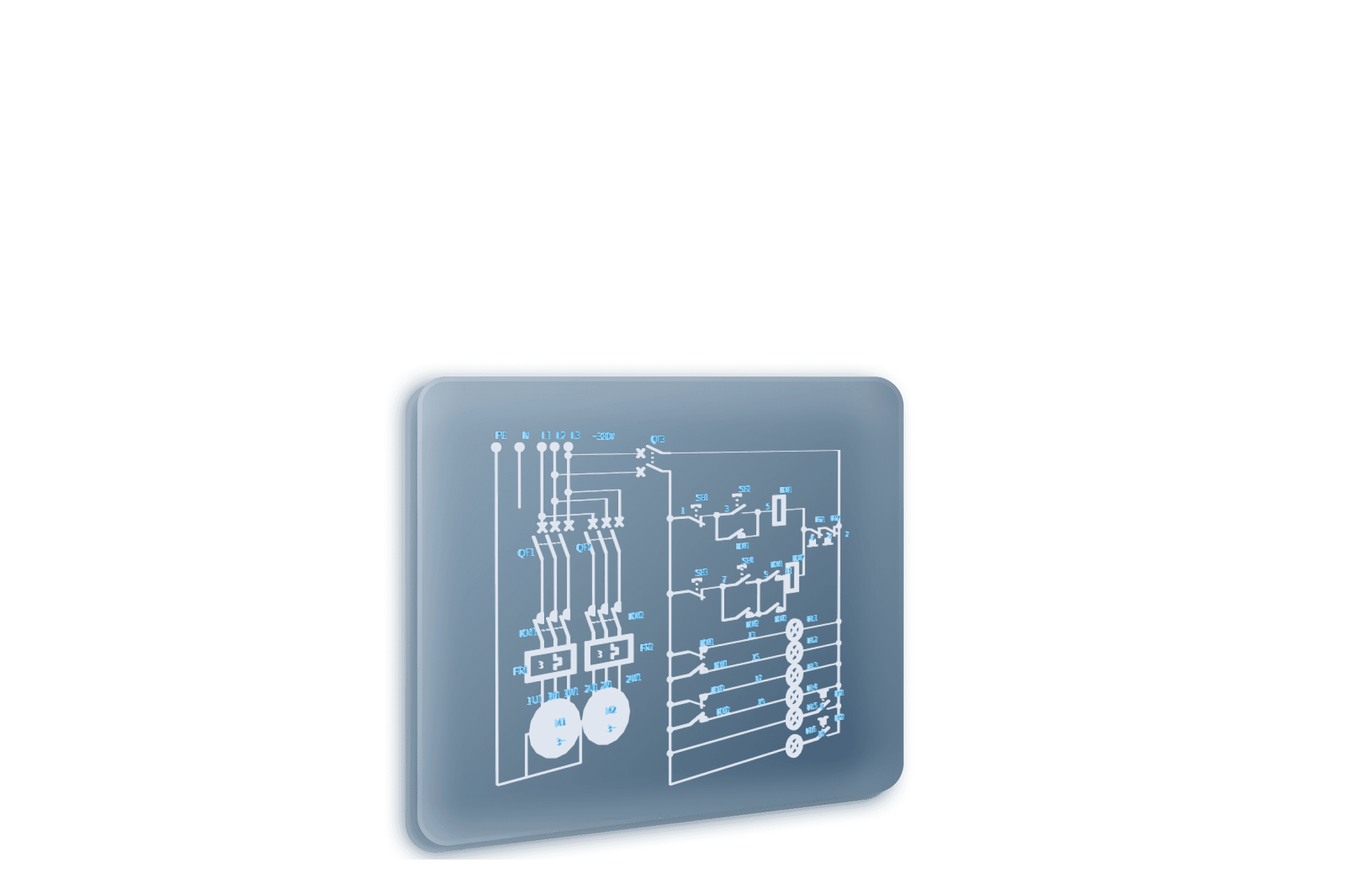

#1- working scenario

Intelligent Glasses

Electrician

Factory machine

loT Cloud database

*Database with digital models and circuit diagrams of plant machinery and equipment

Prompt Area

Workspace

Interface

system in factory

rendering

two modes

Default prompt area

Default workspace

Learning mode

Repairing mode

Switching mode: voice input

Switching mode: gesture recognition

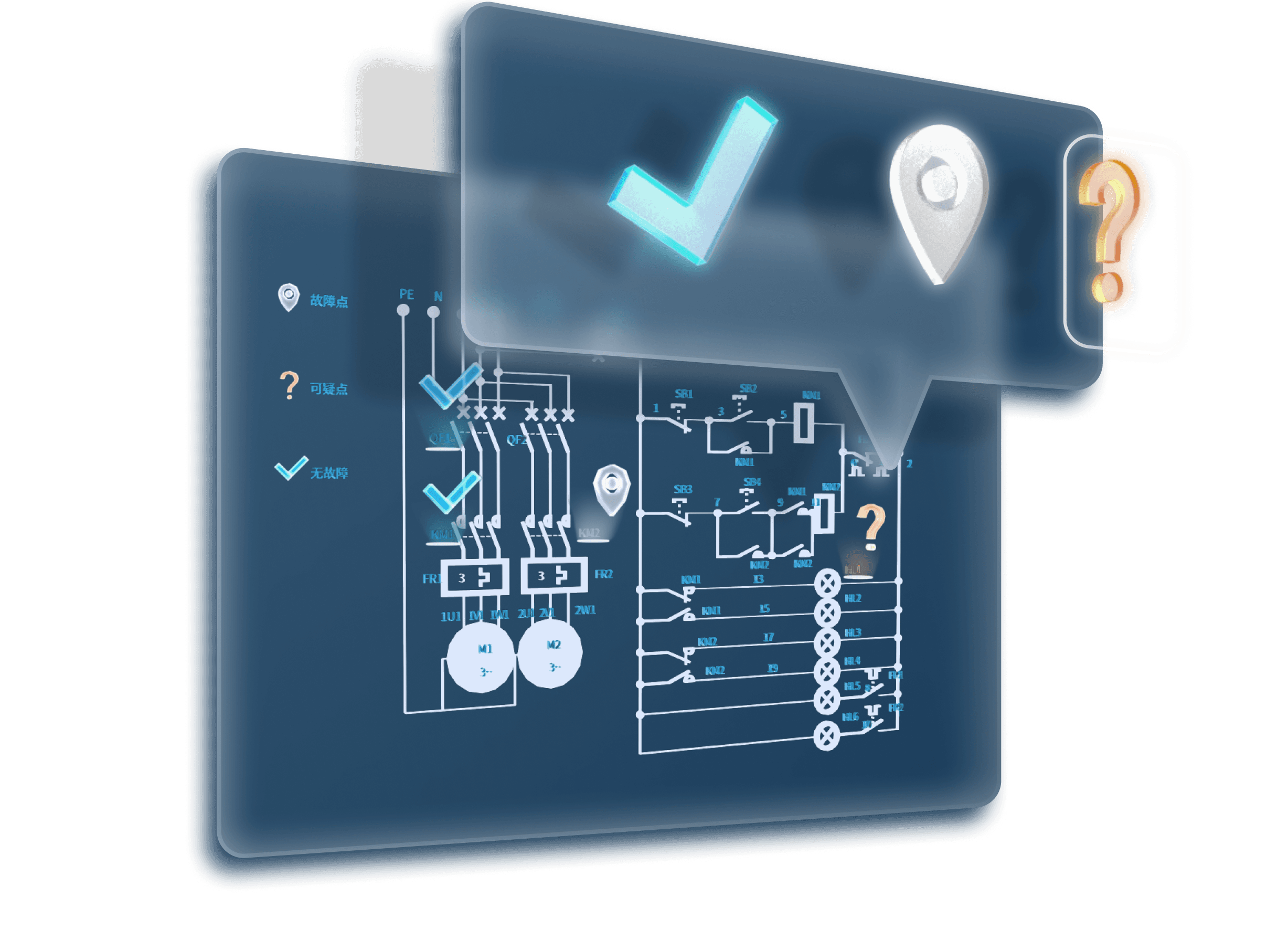

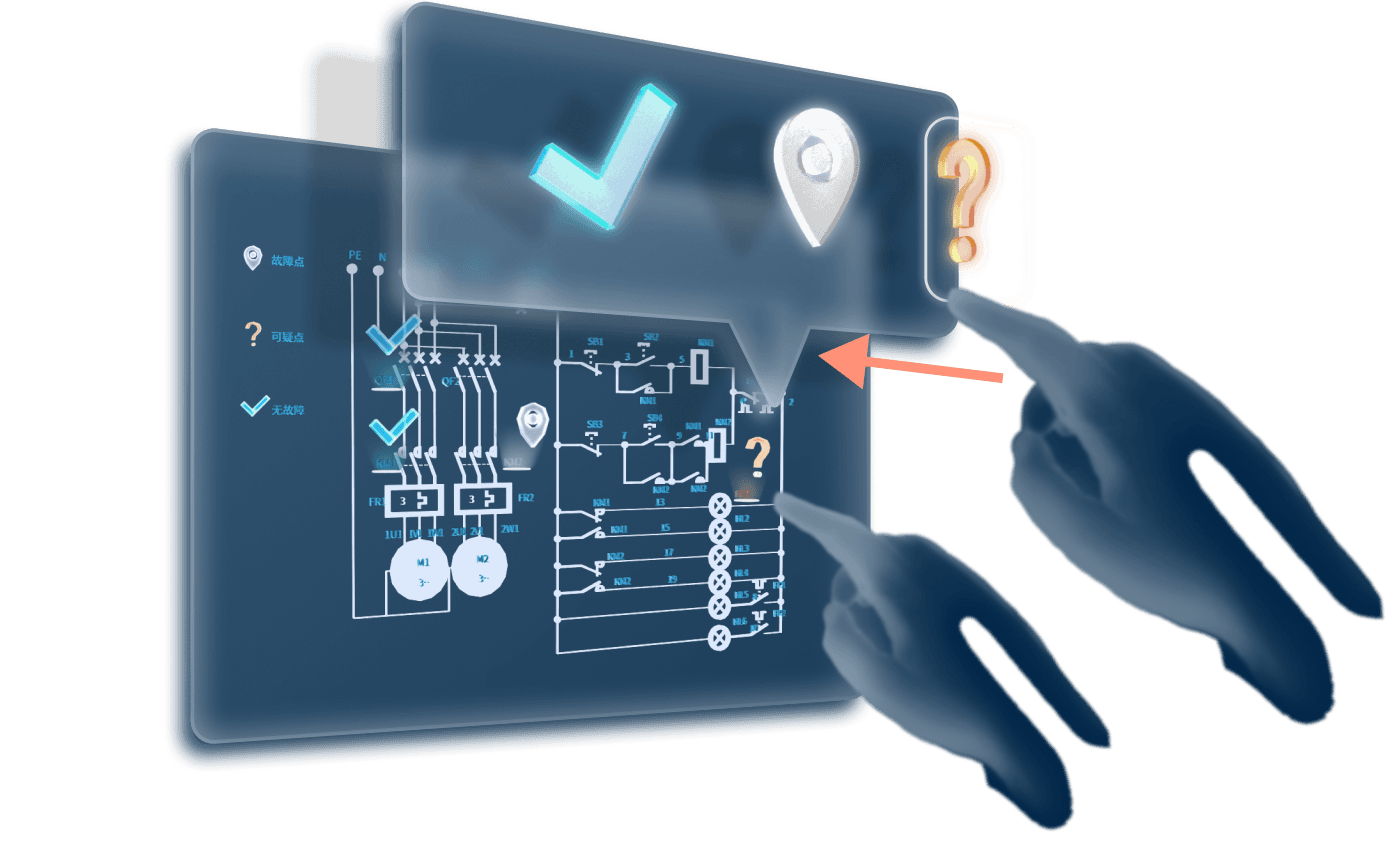

Marking the progress of troubleshooting

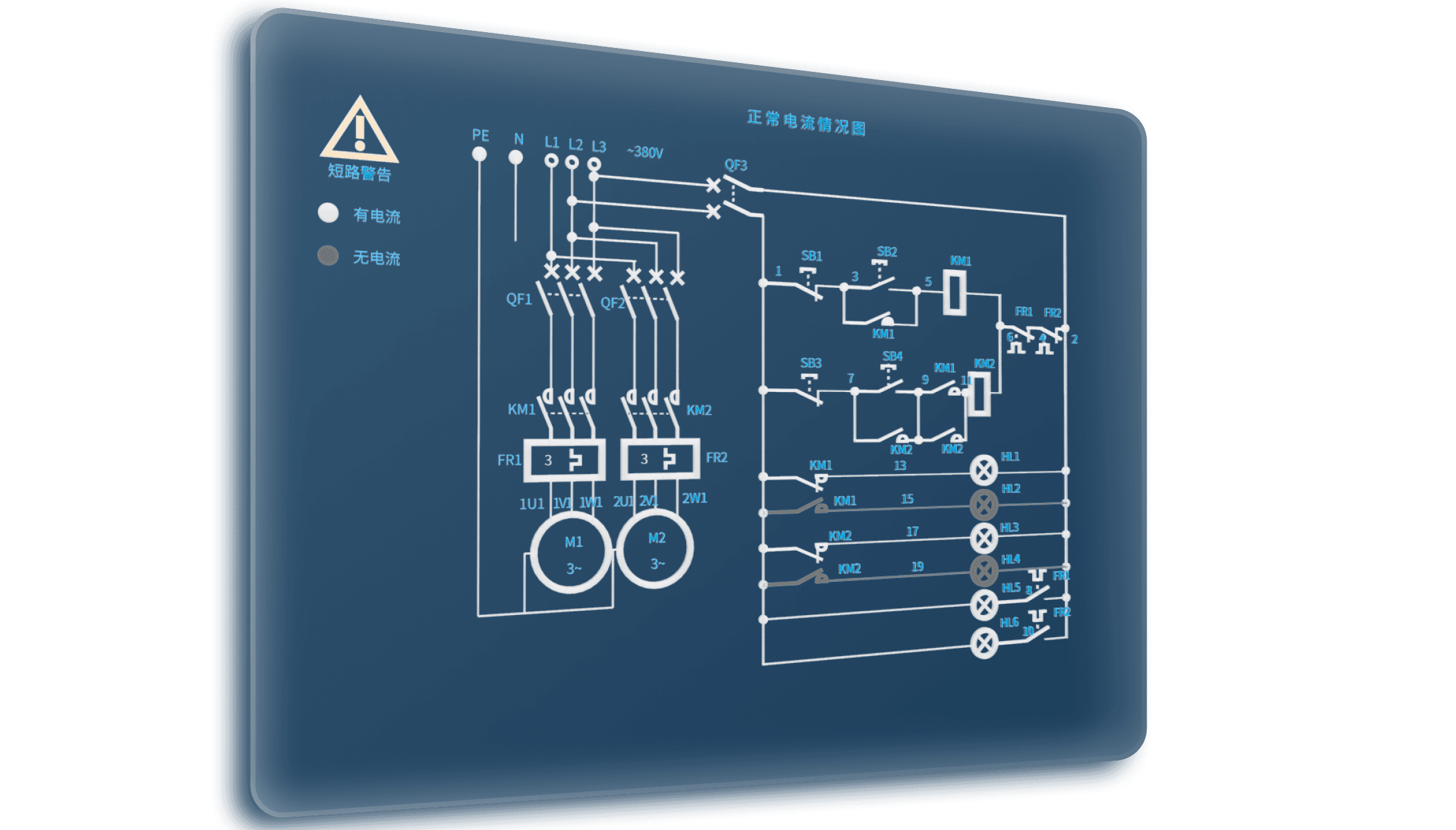

Schematic/wiring diagram

Indicates the impact of the operation

Marking the progress of troubleshooting

Schematic/Wiring Diagram

Marking the progress of investigation

Indicates the impact of the operation

Operation Object

Operation contents

Component symbols and names

Schematic/Wiring Diagram

Symbols and names of corresponding components

object

content

Can be connected for teaching

Cannot be removed

Free Adjustment

Sync with master shifu

Functional Module

Thumbnails

Electrician’s hand

Operation object

Operation content

visualization content based on operational piggybacking

Module 1 - Default workspace

Corresponding component symbols and names

Marking troubleshooting progress

(Minesweeper Layer)

Module 2 - Default prompt area

Thumbnails

Module 2 - Default prompt area

Mark the progress of the troubleshooting

Schematic/Wiring Diagram

Operation effect on circuit / marking troubleshooting progress

Point out the influence of operation on circuit

Core Functions

Drag and drop to the lower left corner of the main workspace/field of view

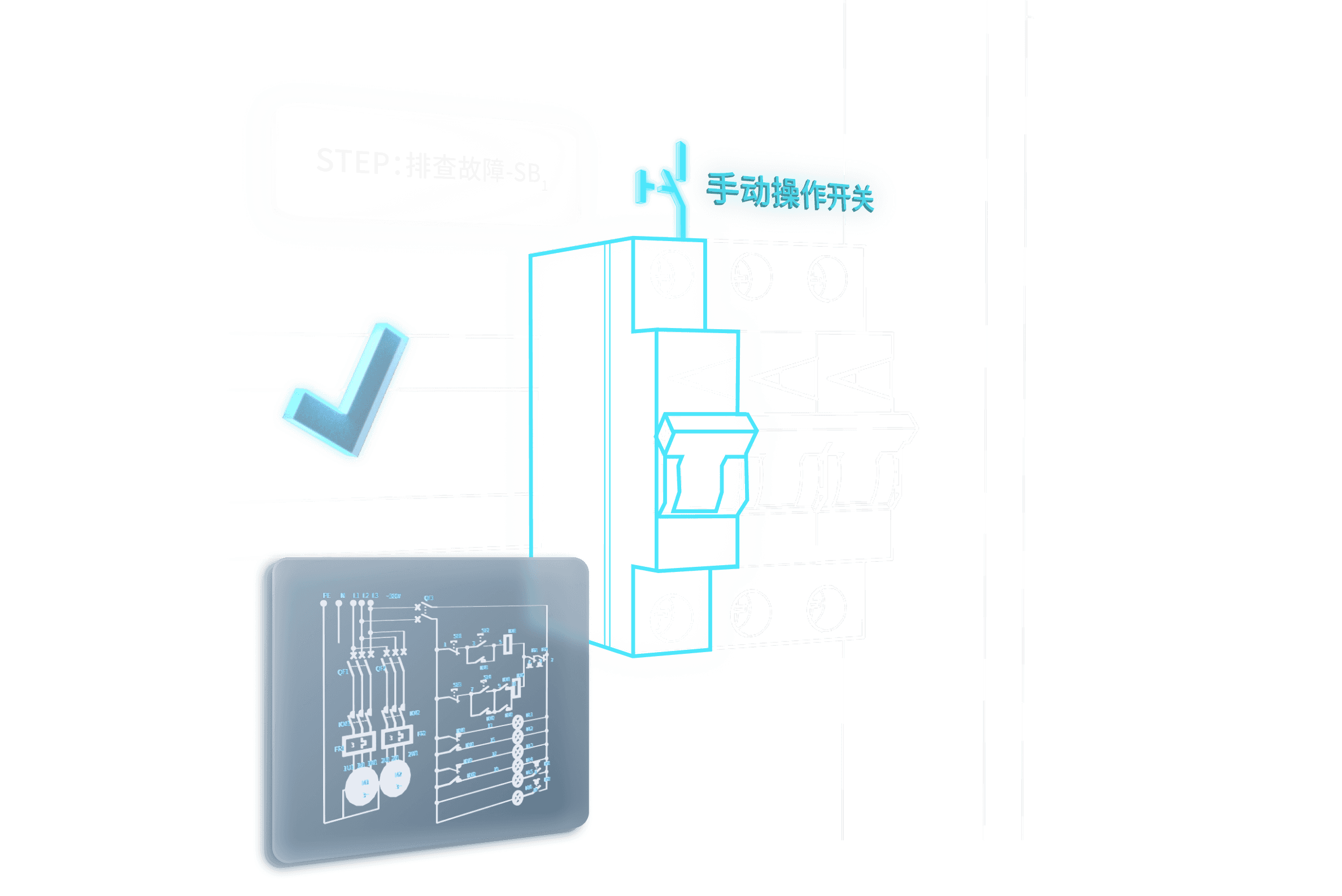

Step4. Click the popup window

Step1. Zoom in on the tip area

Zoom in/out of the cue zone

Switch Workspace Functions

Push up on the prompt area

Switching cue zone content

Step2.Click on the component name

Step3.Drag and drop the selection box

Mark the checking progress

Voice control:

"Open/Close Component Symbol" "Open/Close Scheduling Progress"

Other details

Select Mode

Scan the nameplate

Step1. Click to confirm successful repair

"The fault manifests as ....."

Step2.Dictate additional fault description

Verbalization

"The cause of the problem is ....."

"Repair content is ....."

Step3. Supplement the repair process according to the wiring diagram

Fill out and submit a trouble report

Step1. Click the button to select the mode

Step2. Press the side button to connect with others

Step3. Confirm

Step2. If invited, select whether to pass or not

Clik

Service workflow

Using Process

Phase

Wear glasses

Interaction Method

Backstage

Scan the machine nameplate

Visualization

Confirm the model number

Press the side button

Click

Press side button to initiate

Select mode

Repair Mode

Study Mode

free repair

free study

Receive Connection request

Initiate connection

Confirm Eyeglass number

Confirm Eyeglass number

Load corresponding machine model and corresponding circuit diagram in database

Log in

Interconnection

Sharing of real-time machine information

Repair Preparation

Start/watch a repair

Toggle between workspace and hints on demand

Toggle between workspace and hints on demand

Gesture Control

Gesture

Gesture Control

Voice Input

Voice Input

Image recognition of nameplate content

Image recognition of gestures, operating positions and actions

Voice recognition for corrections

Recording of operation positions and actions in chronological order

Circuit simulation based on recognized actions

Fill in/confirm the location of the fault or the results of the current investigation

Fill out the fault report

Fill in/confirm the location of the fault or the results of the current investigation

Confirm and submit the fault report

Confirm and submit the fault report

Recording of filled data

Fill in the form with the fault location marked by the user

Unrepaired faults are sent to other maintenance electricians in the plant

Synchronization of reports with plant systems

Upload the report and procedure log to the Learning App case library

Microsoft HoloLens2

2xIR cameras

——Eye tracking

1xMP sensor

——Depth Learning

——Recording

1xWebcam

1xAccelerometer + Gyroscope + Magnetometer

——Inertial measurement unit

——MR interactive display

——Device-based command and control;

natural language processing

4xVisible cameras

——Head tracking

Waveguide Perspective full range of lenses

Microphone Arrays & Speakers

hand tracking

eye tracking

smart voice

spatial mapping

MR capture

side button

Sensors

Display

Voice

Understanding

Accuracy

Cooperation

Devotion

Technical Support

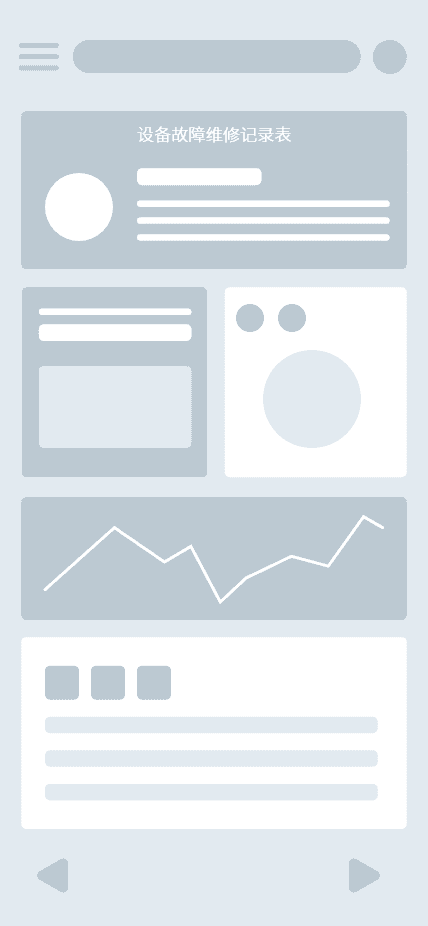

App Functions

Main functions

Other functions

Fault library

Principle feedback

Remote work

Achievements

Job assessment

Troubleshooting cases in multiple working scenarios from real equipment

Helps electricians understand component symbols and circuit connections

Connect with experts to help solve problems

Documentation of solved equipment faults

Display personal skills radar charts and recommend suitable jobs

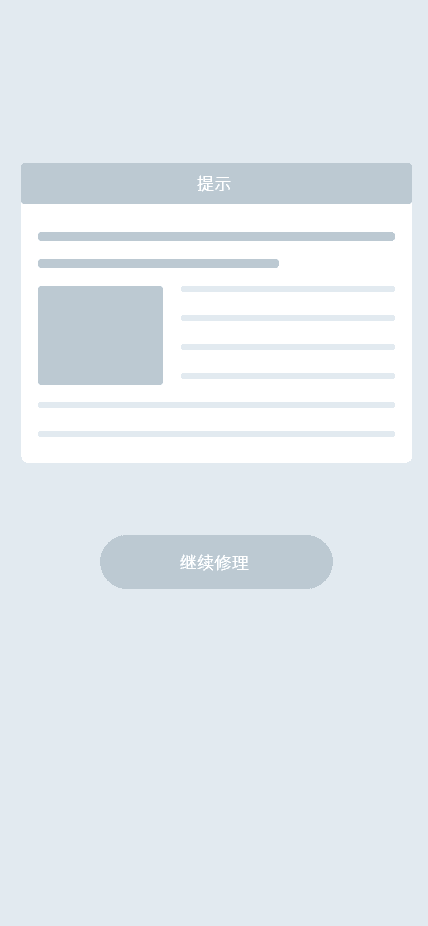

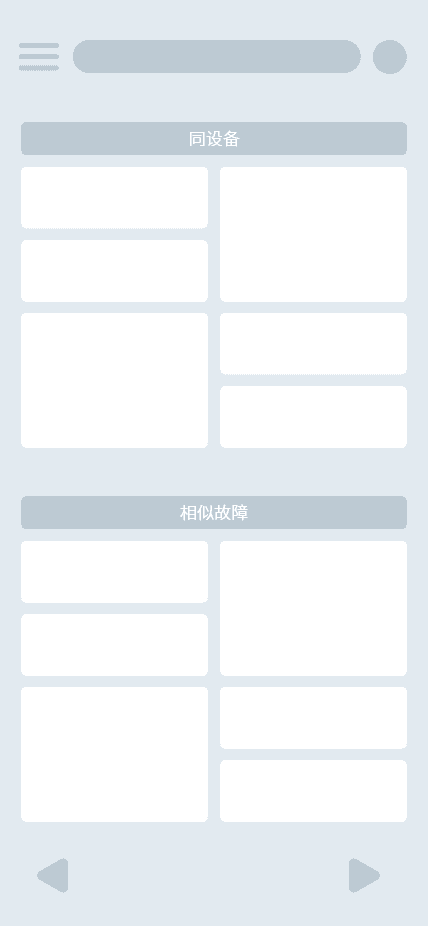

#2- After-work training scenario

architecture

work station

personal interface

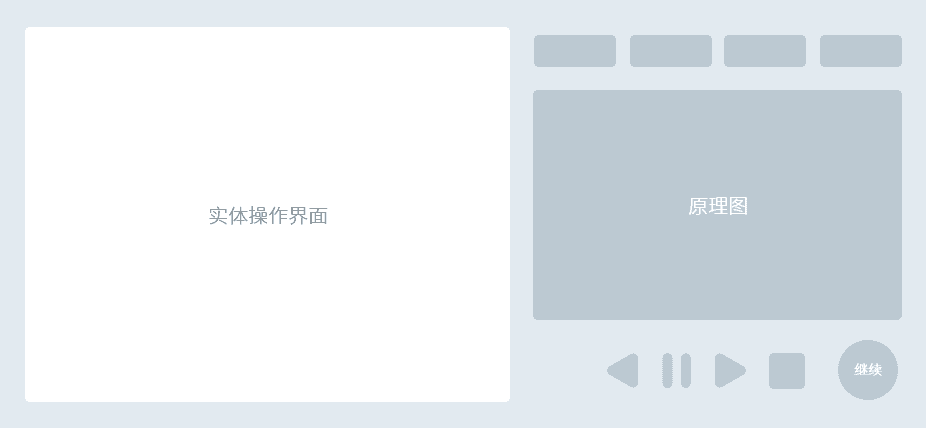

Two modes

Working Environment

Radar chart

Work Process Release

Repair History

Unsuccessful repairs at work

Unskilled repair

Never seen

May encounter in the future

Weak electricity

Force electricity

Number of repairs (proficiency)

Circuit Principle

Repair width

Repair efficiency (speed)

Time

Characterization

Causes

Failure of the same equipment

Similar Characterization

...

Career Development

Search by category

Simulate real maintenance

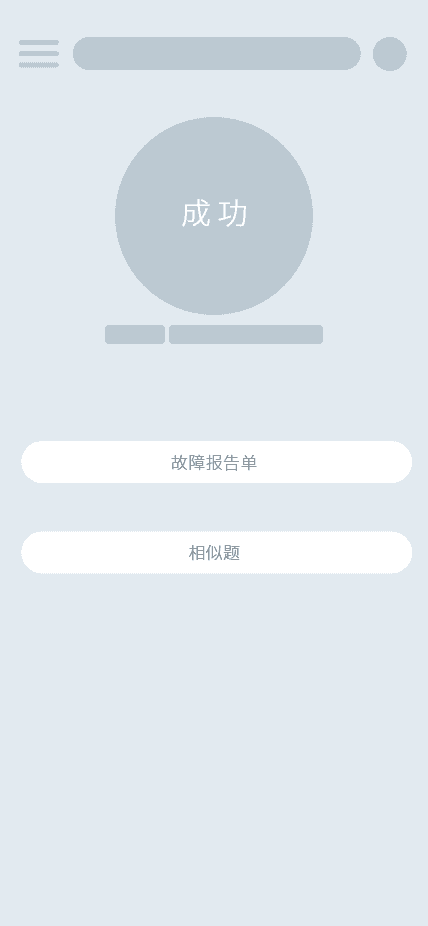

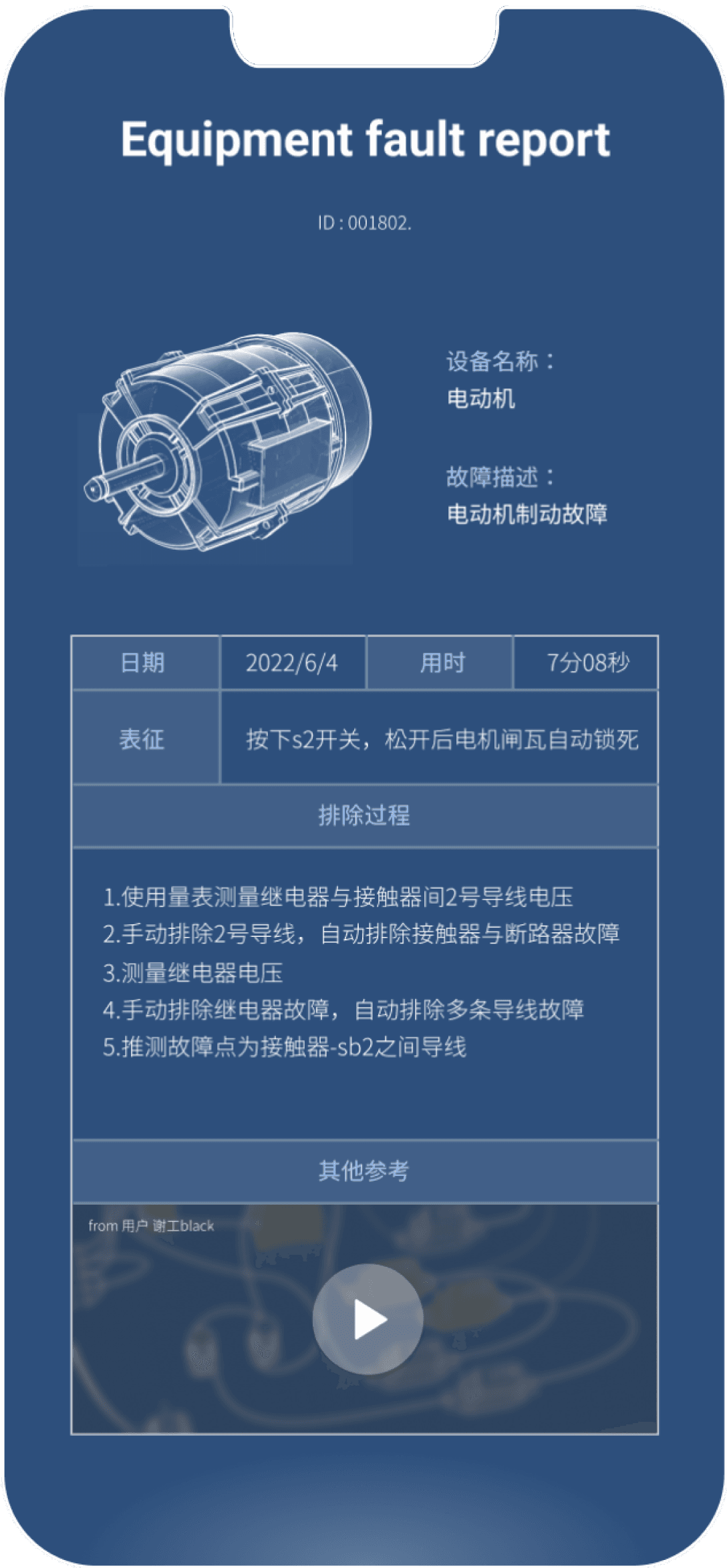

Fault report form

Similar topics

Demonstrate the corresponding schematic diagram

Training

Choose Equipment

generate faults

user operations

summarization

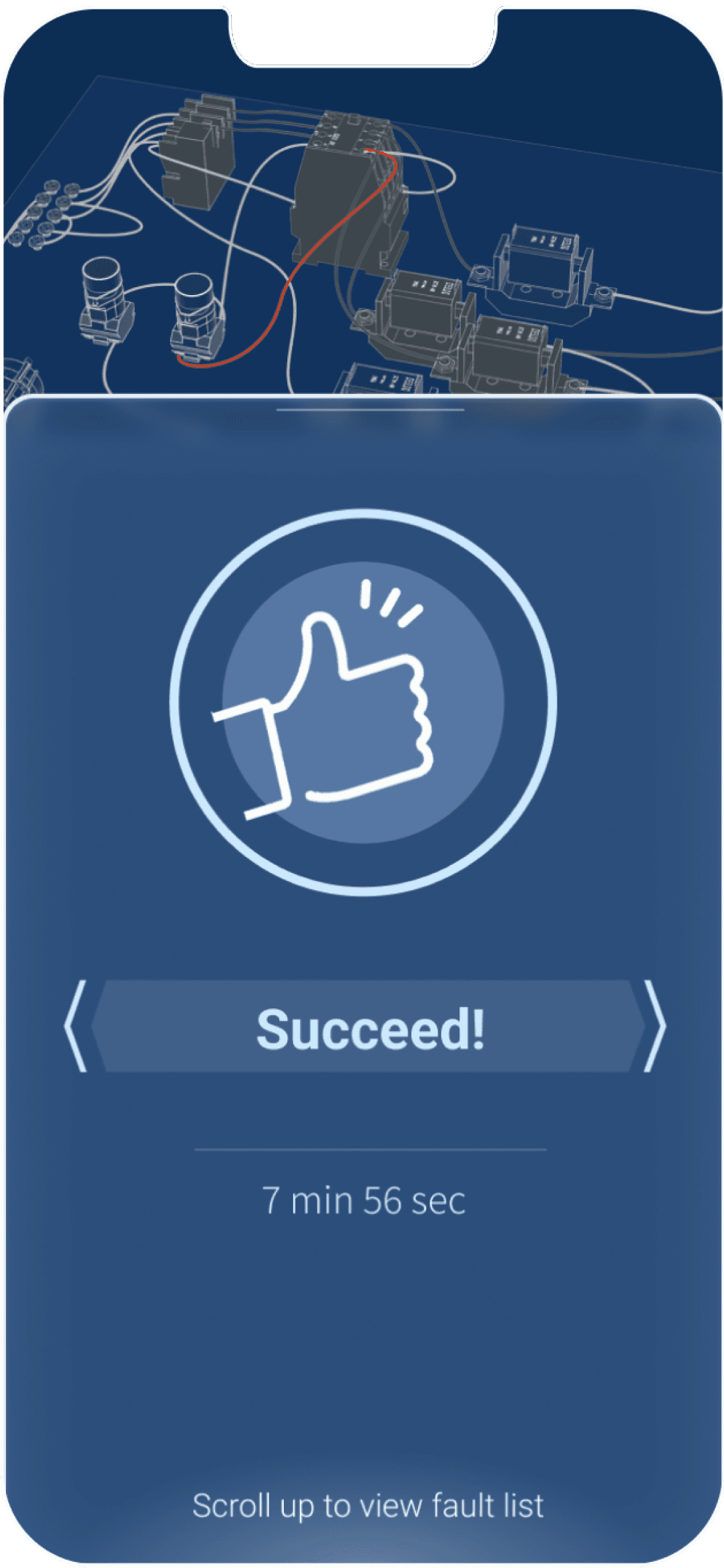

success

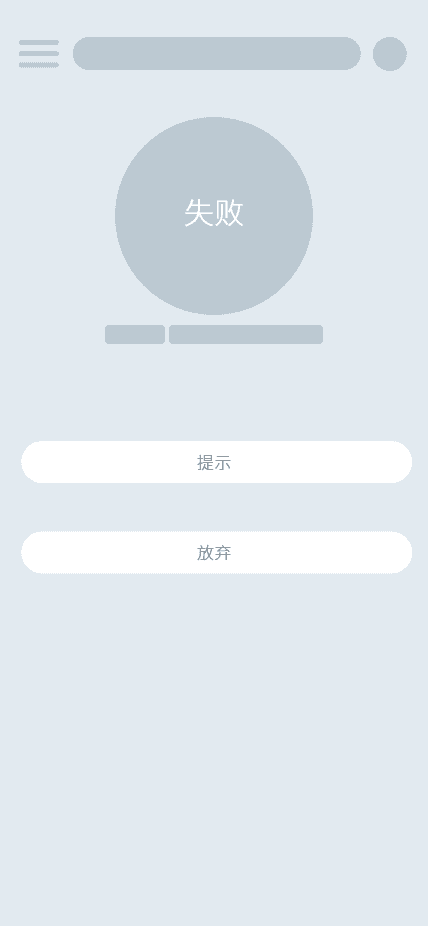

failed

give up

hints

select faults

Choose Equipment

Demonstration

competence assessment

personal achievements

Demonstration

encourage users to operate

similar recommendations

Continue troubleshooting

Main Page Wireframe

Walkthrough

Failure

Success

Report Form

Similar tasks

Tips

Demonstration

UI

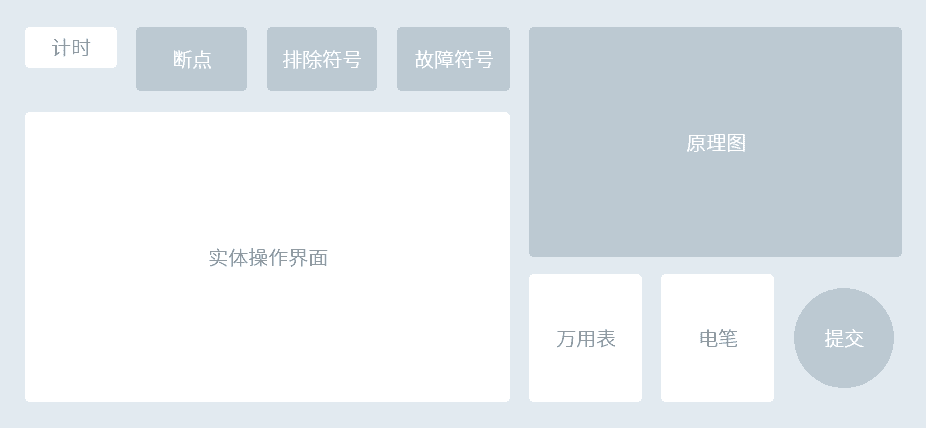

Timer & fault ID

3D circuit Worktop

Testing tool kit

/electricity tester/voltmeter/troubleshooting/marking faults/

/fault judgment time/fault ID/fault name/

/air switches/fuses/relays/circuit breakers/contactors/motors/......

Element information

Testing result

Circuit diagram

Fault appearance

Submit

Report

Fault diagnosis feedback

Enter the operation interface

Slide to change view

Operate tools to measure

Marking detected spots

Mark fault points and submit

Wiring diagram components correspond to the schematic diagram

Feedback

Interviewees

Testing contents

Goals

Is it effective, are you willing to invest money, how much are you willing to spend, why, are there competitors?

What are the desired benefits? Are there prerequisites to consider when putting it into use for workers? (e.g., will the worker stay on for a long time, level of worker position, etc.)

Room for program improvement/how to ensure expertise in this knowledge

Boss & Facilities managers

Factory managers

If you use it, what type of failure questions would you like to get? For the target function, what is your operational process?

Is the characterization of what is broken described clearly;

Does the wiring diagram simulate the real situation and where are the gaps? Do the discarded parts have a big impact?

Is the schematic and wiring diagram correspondence clear; does the troubleshooting pattern of exclude-find out make sense;

Does the way it operates now interrupt normal maintenance?

Does the wearing device itself interfere with the work/will the position affect the operation of the device?

Is the interface easy to understand / are there any functions that you find useless / are there functions that you would like to have / can you find these functions

Are the schematic correspondence and fault labeling features helpful?

How do you ensure that this knowledge is specialized?

Users

Positive young electicians

Interaction rationality

Core functional effectiveness

Business model

Is there a willingness to spend time using the software? If so, when exactly do you use it?

Will the software be useful for real work? What other real-world problems would you like to be able to solve by rehearsing them in your spare time?

What are your favorite parts? What parts are redundant or useless?

Spare-time Section

Spare-time Section

Work Section

Work Section

Management Section

Things that I don’t understand.

New ideas to consider.

Things that I liked the most.

Things that could be improved.

Feedback Capture Grid

Things that I don’t understand.

New ideas to consider.

Things that I liked the most.

Things that could be improved.

Feedback Capture Grid

Wire color division and electrical industry code

Little help to a skilled electrician

From Electricians

From Managers

Be useful to new electricians

Convenient practice

Be useful to new electricians

Solve the problem of Shifu’s unwillingness to teach

Solve the problem of Shifu’s unwillingness to teach

Remote collaboration or guidance of repairing

Not cost-effective

Targeted design for a factory

Routine failure of a piece of equipment is the most valuble experience from Shifu

PLC mode

Recommend cases of the equipments in the factory I worked in

Why don’t send these electricians to training institutions

Effectiveness for complex problems and equipment

Little help to a skilled electrician

The quantity of equipments’ models

New ideas to consider.

High-end factories

Low-end factories

AR scenarios Refresh

Learning-Oriented

Work aid, learning by doing

Component symbol display

Component symbol display

Circuit diagram

Circuit diagram

Fault markers

Fault markers

Orientation Phase

Remote Collaboration

History of faults

Annotations / Tips

Steps to operate now

Steps to operate now

Original Scenario

Renewed Functions

Renewed Scenario

AR interaction specifications

Correction of the function obtained by feedback

Interface & Interaction adjustments

Original Scenario

Renewed senario

App ui Refresh

Industrial standard of electrical device

User feedback from interviews

Interface & Interaction adjustments

Elements Layout

Wire Color

Information on the left side

Operating points on the right side

Expand the operating area to make it easy to view

Separate the position of detection tool and mark

Enlarge the button

Remote Collaboration

Annotate in reality through the screen

Video call

Linked Learning with Master

Independent learning mode

Learning-maintenance mode

APP self-study

APP self-study and consolidation

APP Learning Update Cases

APP Learning Update Cases

Maintenance mode

becoming a specialized/advanced technician

renewed journey map

Rookie

work

after work

Apprentice

Independence

development

stakeholder

The contribution and return of stakeholders

Equipment manufacturers

Provide original database

Buy equipment and data

Repair machines for the factory

Accumulating data errors on equipment for equipment upgrade

Provide faulty equipment requiring repair

Provide HoloLens to workers

Factory owners

Electrician

development

Scenarios

Values

Users

Working

Scenario

Spare-time

Scenario

Orientation Phase

Remote Collaboration

Low-end

Low-end

electricians who

need to progress

especially new workers within 5 years of joining

Remote collaborators

Workers in

other fields

e.g. factories/companies such as Toyota, TSMC, Siemens

Worldwide, High-end

Professional

technician